Weapon Construction Basics

This chapter is an overview of where to find weapon construction materials, advice on what materials to use in weapons construction, and basic construction techniques. Actual instructions for specific weapons are contained in the weapon construction appendix of this manual. Before starting on your first weapon you should read this section a few times to make sure you are familiar with its content. If you follow all the directions outlined in this chapter you can make a high quality weapon on your first try.

Materials

There are a few basic types of materials that all weapons will require. They are: Core, Adhesive, Foam, Cover, and Tape. Use the table below as a reference for where you can find these items and what they are used for. Some items are found exclusively online, so web links are provided. These are the recommended materials for weapons construction. If you would like to use something that does not appear on this list you should ask someone knowledgeable before trying.

Where to Find Weapon Materials

Abbreviation Key

| FF | = | Farm n' Fleet (farm supply chain in the Midwest) |

| DB | = | D & B Supply (Farm and agriculture supply chain in the west) |

| HW | = | A hardware store: Home Depot, Lowes, etc. |

| s/t | = | Stabbing Tip |

| WM | = | WalMart |

| Item | Used for | Found At |

| Cores | ||

| 3/8" x 4ft Fiberglass Rods | Swords (single or double core) | FF (Agricultural Fencing), DB (Agricultural Fencing) |

| 5/8" x 6ft Fiberglass Rods | Class 2 Swords, Spears | FF (Agricultural Fencing), DB (Agricultural Fencing) |

| PVC Pipe | Weapon core | HW |

| 3/8, 1/2, & 3/4" Plywood | Shield core | HW |

| Indian Fiberglass Arrows | Arrow core | WM (Sporting Goods) |

| Online Cores & Archery | ||

| Kitespar | Weapon core | http://www.gwtw-kites.com/showproduct.asp?ProductName=Glasforms+Fiberglass+Rod |

| Fiberglass Rods | Weapon core | http://www.kencove.com |

| Bandshoppe pole | Weapon core | (See link) |

| Cabela's Maverick Carbon Arrows | Arrow core | http://www.cabelas.com/ Archery--> Arrows/Shafts--> Cabela's--> Maverick Carbon Arrows |

| Adhesives | ||

| DAP Contact Cement | Gluing closed cell foam | HW, WM |

| Carpet tape | Repairs, Rope Wrap Handles | HW |

| Duct Tape | Everything | HW |

| 3M 77 & 3M 90 Spray Glue | Glue Open Cell Foam | HW, FF, WM, DB |

| Foam | ||

| Ozark Trail Camping Pad | Most Weapons | WM (1/2" Closed Cell Foam) |

| "Egg Crate" Open cell foam | Javelins, Daggers | WM |

| Nerf POOF Footballs (Big) | Spear Heads | WM, Target |

| Nerf POOF Footballs (Small) | Axe/Mace stabbing tips | WM, Kmart |

| 3/8" Black Pipe Insulation | Haft Padding | HW, WM |

| 5/8" Pipe Insulation | Thicker Haft Padding | FF, DB |

| Kickboards | Shield core | WM, Kmart |

| Fun Noodle | Flail Heads | WM |

| High Density Open Cell Foam | Stabbing tips, arrows/javelins | Fabric Store, couch cushions |

| Grey Computer Packing Foam | Stabbing tips, arrows/javelins | Computer store dumpster |

| Shield Cores | ||

| Plywood | Core | HW |

| "Techply" | Core | HW, (Menards - http://www.menards.com/main/building-materials/panel-products/underlayment-panels/plywood-underlayment/1-4-4-x-5-plyfloor/p-1479671-c-5711.htm) Basically it's 5-ply underlayment. |

| Covering & Finishing Materials | ||

| Electrical Tape | Pommel Covering | WM, HW |

| Black Cloth Athletic Tape | Grip, haft taping | WM, Sporting Goods stores |

| Fabric: Trigger, Great-cloth | Covers | Jo-Ann Fabrics, WM |

| 1/8" & 3/8" Diameter Rope | Drawstrings, grips | HW, FF, DB |

| Measuring, Cutting, Marking & Other | ||

| Scissors | Foam Cutting | WM, Fabric store |

| Yardstick or ruler | Measuring | Fabric store |

| Sharpie Markers | Marking | HW |

| Cloth measuring tape | Measuring | Fabric store |

| Hacksaw | Cutting Core | HW |

What materials to use

You will find many variations of these products. Specific brand names and recommended uses are in the table for a reason. It is very important to stick with particular brand names when it comes to glue. Types of cores, tapes, foams, and fabrics will vary a lot more and there are good brands out there that may be unknown or undiscovered to other fighters across the country.

Glues

DAP Contact Cement and 3M Spray Glue are the best glues to use, period. Cheap imitations will result in poor quality weapons.

Tapes

3M heavy duty or all weather duct tape is a widely used strong duct tape although it is relatively heavy and expensive. Feel free to experiment with duct tapes until you find a happy medium of durability/strength, cost, and weight. People often wrap the uncovered portions of their weapons in tape (pommel, handle, and haft) for better appearance and stability. For pommels use duct tape or cloth tape. Cloth tape will create a nicer look and feel to a weapon than duct tape when used as a pommel, handle, and haft wrapping. You should not use electrical tape to wrap your hafts or pommels. It will eventually crack and tear, causing the weapon to become scratchy and hard. You should never use electrical tape as a structural element in a weapon. Handles can be wrapped in you preference of grip (tape, rope, etc.) or left bare. Hafts (especially on javelins) should be covered in some form of soft tape, preferably cloth tape. This is to prevent injury in the case of incidental contact with a non-striking surface. If you do not have access to cloth tape, use a soft, flexible duct tape. You should never use fiberglass strapping tape. This is tape that has thick fiberglass strands running through it. These can break and splinter, poking out of the weapon.

Foams

There are two basic types of foam, open celled and closed celled foams. Closed cell foam does not absorb water and open cell foam does. Closed cell foam is denser and is the preferred foam for most weapons and shields. Open cell foam is softer, but is easier to compress all the way. It is most preferred for stabbing tips, javelin heads, and arrow heads. The most commonly used closed cell foam is Ozark Trail camp pad from WalMart, also known as ‘blue foam’. It is relatively cheap and very easy to find. Do not buy closed cell foam that has bubbles or makes a snapping noise when you squeeze it. The most widely available, quality open cell foam is high density upholstery foam purchased at fabric or craft stores. It is usually green and comes in varying thicknesses.

Fabrics

Trigger poplin is one of the most widely used fabrics for covers. It is strong, durable, soft, and easy to find at any fabric store. Trigger poplin is somewhat pricey; so many newer fighters prefer to use broadcloth. It is lighter in weight and less expensive, but is not as durable. There are other light fabrics out there, as well as stretchy fabrics that will cover odd shaped more easily. You should avoid using patterned fabrics. Plain solid colors are preferred. Experimenting with various fabrics is a good thing- however you can always fall back on trigger poplin or broadcloth.

Bonding Methods

One of the biggest debates of weapon construction is what the best bonding adhesive is. Many people use DAP contact cement, others prefer spray glue, and yet others rely on carpet tape. Each one of these methods has their advantages and disadvantages. Some people just have better luck with one type of adhesive as opposed to the other. This manual will recommend bonding techniques that have stood the test of time by its authors and what they think is the consensus of the majority of the Belegarth community. Our bonding recommendations are as follows:

- When bonding closed cell foam to closed cell foam or to a core- use DAP Contact Cement.

- When bonding open cell foam to any other surface- use 3M 77 or 3M 90 spray-glue.

- When bonding a grip to your core or wrapping rope around a core to make a wider handle- use indoor/outdoor carpet tape.

- DAP does not bond to duct tape. If you need to DAP over a duct taped area, you should cover the duct tape in cloth tape first, which will absorb the DAP and provide a better bond.

When initially building a weapon and bonding foam to your core you should use DAP. Carpet tape and spray glue are handy as back-up adhesives for quick repairs. All adhesive methods are strengthened by reinforcing with duct tape, however try to avoid putting duct tape on a weapon’s striking surface. Duct taped areas will not compress as easily as non-duct taped areas and will cause stress points that will cause the foam to rip.

Your first weapon

If possible, build your first weapon under the supervision of an experienced weapon maker. If there is not one around you should print out instructions and follow some of the basic tips described below. Do not be discouraged if your first weapon does not turn out like you had imagined. Almost everyone's first weapon tends to be a bit shabby. Also do not worry about what a weapon looks like without tape or a cover. Taping and covering your weapon (which is required anyway) will dramatically improve its appearance and stability.

Weapon Building Basics

Selecting a core

Your choice of a core will play a vital role in how durable your weapon is, the weapon’s weight, and how much flex it has. Flex is the key factor in deciding how long you can make your weapon core with certain materials and still maintain a legal amount of flex. (As stated in the Book of War, a weapon may not flex more than 45 degrees when struck on a surface). Various cores are described below along with what types of weapons they work best for and what diameters are best to use depending on the weapon you want to build.

PVC Piping

PVC pipe is the cheapest and most common weapon core. You can find PVC in any local hardware store. The most common kind is schedule 40 (marked on the tube), however schedule 80 is stronger and is recommended for usage if you can find it. When shopping for PVC, buy the highest rated PSI available. It will be slightly heavier, but will be much stronger and less flexible due to thicker sidewalls. Do not use grey electrical conduit. Electrical conduit will look like PVC except it will come in a grey color whereas PVC is typically white. Electrical conduit has a very low melting point and will deform easily when left in the sun or in a hot car. The downside to PVC is that it becomes bulky and heavy in larger and longer weapons and over time will weaken, eventually over-flexing or breaking.

Size recommendations:

- Never use 1/4” PVC -Use 1/2” PVC for up to 38” cores (most class 1 weapons and daggers)

- Use 3/4” PVC for 38”-54” cores (short class 2 weapons)

- Use 1” PVC for 54”-72” cores (most class 2 weapons and short spears)

- Use 1 1/4” PVC for 72”-90” cores (short pole arms and spears)

- Use 1 1/2” PVC for >90” cores (long pole arms and spears)

Fiberglass

Solid fiberglass rods tend to be slightly more expensive than PVC, but they are the recommended core for most weapons. They are often advertised as agricultural fencing rods, or sometimes you can find 3/8” diameter rods in the form of driveway markers. You may find fiberglass rods in some hardware, farm supply, and co-op stores. Fiberglass can be hard to find, but you should look around your area before falling back on PVC. Fiberglass cores are more durable than PVC and typically will not break unless under tremendous stress. They will flex more over time however, just like PVC.

- Use 3/8” diameter rods for up to 28” cores (short class 1 weapons)

- Use 1/2” diameter rods for up to 44” cores (medium/long class 1 weapons)

- Use 5/8” or 3/4” diameter rods for <55” cores (class 2 weapons)

- It should be noted that 1/4” or 3/8” rods can be paired up and cemented together with Liquid Welder or another epoxy in order to make class 1 weapons that are greater than 28” core. This technique yields what is known as a “double core”.

- It is sometimes possible to acquire square cross-section fiberglass bars. These are superior in all ways to round rods.

- 3/8" square fiberglass can be used for weapons with up to 40" cores

- 1/2" square fiberglass can be used for weapons with up to 55" cores

Wood cores

A very uncommon core (with the exception of spears). Good wood cores for weapons are typically hard to find and vary in price. The only recommended wood cores for weapons are bamboo for spears. Remember that all wood cores must be wrapped in tape to help prevent injury in the case of a core break. Axe handles, baseball bat handles and other hard treated types of wood are specifically disallowed. Do not use wooden dowels or broomsticks, they will break and will hit extremely hard without large amounts of padding. If you do not have a local source for bamboo you are often better off just using fiberglass or bandshoppe pole.

Kitespar

Kitespar is a high performance core. It is extremely lightweight and reasonably durable. It is relatively expensive, however. Typically kitespar is used for very light class 1 weapons. Using most kitespar weapons two handed will risk breaking the core. It is easiest to buy online (refer to the link above), but can be found in kite stores and sometimes at specialty fiberglass producers.

Size recommendations:

- Use .524 OD rods for up to 40” cores (class 1 weapons); .505 also works but is more likely to break because it has thinner sidewalls than .524

- Use .606 OD rods for >40” cores (short class 2 weapons, short spears, and javelins)

Graphite

Graphite cores can be found in the form of graphite golf clubs. They are easiest to find from a friend who broke a club, at a golfing pro shop that sells used clubs, or simply at Goodwill or other thrift shops. Graphite cores are extremely lightweight; however they are more prone to breaking than kitespar. They are typically used for class 1 weapons only. The longer your graphite weapon core is the more prone it will be to breaking. Bring a magnet when thrifting to differentiate between metal and graphite clubs. Pro-tip: sand wedges are the strongest clubs (because they're designed to be hit into sand).

Bandshoppe Poles

Bandshoppe flag poles are fiberglass marching band flag poles, and can be found online (see Bandshoppe_pole. You may also be able to purchase them through local schools’ marching bands. They are hollow fiberglass tubes that make excellent cores for any size of class 2 or class 3 weapons. They are effectively indestructible, however they are fairly expensive and generally only available online. The cores come in up to 8ft lengths, though finding eight foot cores has become a problem in recent years because of changes in shipping policies (eight foot or longer objects have become hideously expensive to ship).

Carbon Fiber

Need info filled in

Working with your Core

Cutting fiberglass

Fiberglass splinters easily work their way into your skin, hurt, and are difficult to remove. To avoid them follow these pointers: Wrap a piece of tape around where you intend to cut your fiberglass rod, then use a hacksaw to cut the center of the tape. Gloves and safety glasses are extra precautions you can take. Dust off the rough ends of your fiberglass with a rag. Avoid touching fiberglass dust or cut rods with your bare hands.

Roughing your core and foam

Many people ‘rough up’ their core and/or foam before gluing because scraping some of the finish off the core and foam provide a better bond. You can use a file to score and scratch your core and foam. Roughing your core is extra work and it is debatable whether it forms a better bond or not. Feel free to experiment with this technique and see if a rough core makes longer lasting weapons for you.

Capping your core

Most weapon cores have pretty small and sharp ends that tend to cut or shred foam. To combat this, you should “cap” your core. For PVC cores you should use a coin or a washer that is slightly smaller in diameter than the pipe. Tape it down securely to the PVC so that it plugs the hole. For fiberglass and kitespar cores you should take a small piece of closed cell foam, about 1 inch square. Using duct tape, tightly and securely tape it over the end of your core to soften the edges. The finished cap should be less than a half inch across.

Re-using cores

Usually the foam on your weapon will break down or become detached from the core before the core breaks. In this case, you can re-use most cores such as PVC, fiberglass, kitespar, or bandshoppe poles by cutting & filing off the glue residue and foam left stuck to the core, then re-gluing new foam onto the old core. You should try not to score the core too deeply when removing old glue residue, however. Doing so can shorten the life of the core.

Bending PVC

Get a wide piece of PVC (1.5" or so). Duct tape the bottom over repeatedly or use PVC cement to glue a PVC cap on. This will be your "PVC oven." Boil a pot of water on the stove and have a large measuring glass and tea kettle with spout ready. Put your 1/2"-3/ 4" PVC weapon core into the PVC oven. Pour in boiling water until it is full and cover with a baking mitt or some insulator. Dump out the old water and replace with new boiling hot water every 15 minutes or so. After 45-60 minutes you should be able to easily manipulate the pipe. You will have less than a minute to bend your PVC once you remove it from the heat. During this time it can be easily manipulated by hand, bent over a knee, or put into a peg setup (see below).

Another method is to fill a bathtub with very hot water to soak the PVC in. It is very difficult to maintain enough heat this way to make the PVC pliable enough to form into the desired shape.

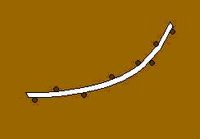

For a more gradual curves that can be flexed into the PVC with your bare hands, you can cap the ends of the core and pour boiling water in, place it in a peg setup, and leave it overnight. For all of these methods the heated PVC will need to be left in the desired curve overnight. The easiest method is probably to use tent spikes or anything you can hammer into your own backyard to form the desired curve (see fig 2.1).

If you wish to have a repeatable mold you can get a sheet of plywood, drill some holes in it, and stick pegs or wooden dowels through it to make your desired curve (see fig 2.1).

Working with Adhesives

Gluing

It is very important to always read and follow the instructions of any kind of glue you are going to use before you use it. Following the directions will give you the best performance from your product. When you are applying your glue, you should aim for an even coat of glue across your entire desired gluing surface. You can apply DAP with disposable foam brushes, cheap paint brushes, or more conveniently, spare scraps of closed cell foam. After the glue is applied, let it (DAP or spray glue) become fully tacky-dry on both surfaces before sticking them together. Wet glue does not hold to wet glue! Again, following the directions on the bottle will lead to the strongest bond.

A tip to make your use of DAP contact cement more efficient is to find an empty Elmer’s wood glue or carpenter glue bottle- one that has a screw off cap with a slit hole and orange cap. Wash out the bottle and fill it with fresh DAP. You can DAP sword blades and long strips of foam very quickly with just a swipe, squeezing out a line of glue then spreading it with a wood dowel or piece of scrap foam. Also great for traveling to events, repairs, and getting DAP into small places. The DAP will stay in liquid form in the bottle for a few months if kept tightly closed and especially if fresh DAP is added now and again. Always shake before using the bottle.

Using Tape

When using tape as a structural element you should usually use multiple strips either laying "X" pattern crosses over the area or spiraling one way with angled strips of tape, then spiraling back over the other way. Rub tape down onto the foam with your finger for a stronger bond. After you have finished the structure of your weapon you should always tape hafts and non-striking surfaces, especially on projectile weapons, with cloth tape (athletic/hockey tape) or duct tape to prevent the foam from tearing or wearing out as quickly. Use duct tape sparingly and avoid using duct tape on striking surfaces when possible. It adds weight and will make striking surfaces hit much harder. The place you will add the most tape on most weapons will probably be on your pommel and flats.

Measuring & Cutting

Attention to detail is probably the most important factor besides quality materials in making a quality weapon. Be very precise about measuring and cutting and you will make much higher quality weapons that are less bulky and last longer. Keeping this in mind, you should always measure, then mark, then cut. When cutting foam use sharp scissors or a utility knife and try to keep a bit of constant pressure pushing forward along your line. You will get a cleaner edged cut. Some scissors are sharp enough to directly shear along foam without snipping, which will produce even cleaner edged cuts.

Once you get into a uniform system of measurements for your desired weapons, make cardboard templates for them. For example you can use a rectangle for your standard sword blades, a rectangle for pommel strips, or a shield template with holes where screws and straps go such that you can easily mark all necessary measurements on the back of your shield in one easy step.

Adding a Grip to the Handle

Creating a good solid grip on your handle is relatively simple. For PVC cored weapons, all you need to do is wrap cloth tape around the pipe. This adds some friction and helps avoid the weapon slipping from your handle. For fiberglass and kitespar weapons, wrapping rope around the handle is the preferred method. The best rope to use is half inch poly/cotton sports and climbing rope that can be found in most hardware stores as well as WalMart. Wrap your handle between the pommel and blade with heavy duty indoor/outdoor carpet tape and remove the backing. Tightly wrap your rope around the core starting at the base of the blade and spiraling towards the pommel. You should always wrap a little tape around your rope before you cut it to keep the rope from fraying. Secure the ends of your rope wrapping at the top and bottom of the handle with some duct tape to keep it from peeling up. You may wrap your rope handle with cloth tape for a cleaner look if you wish.

Covers

Sword Covers

The best way to sew a cover is to use a sewing machine. If you do not have one, check around with friends and realm members before resorting to hand stitching. Machine stitching is much more durable. You should always reinforce your stitching on covers with a double stitch or zigzag to increase their longevity. For basic sword covers all you need to do is cut out a rectangle of fabric the length of your blade plus four inches and with a width of the circumference of your blade plus one inch. Then you sew lengthwise up the cover one half inch in from the edge and then across the top, one half inch in from the edge. Turn it inside out and you have a sword cover! Other weapons will use similar techniques modified to the weapon’s shape.

Flail bags

Bag head style flails use a bag of fabric to hold the ball of the flail to the shaft. In this design, the bag is not merely a cover but is also a functioning part of your weapon. To make it last, you should make sure you are using sturdy fabric and make sure to reinforce your stitching.

Increasing Weapon Longevity

Here are a few basic tips to increasing your weapon’s life span:

- Never stick foam together that has wet DAP on it. It will not hold.

- Always thoroughly squeeze and hold surfaces that have been glued together. The longer and more thoroughly you squeeze the two pieces, the more glue particles are able to bond and the longer your weapon will last.

- Pommels and sword tips are the first things to fail due to age and use. Securely tape your pommel on from all angles (spiral method described above) then tape around it tightly. On sword tips place an ‘X’ of duct tape over each tip-end flat, and then glue and tape down a rectangle of foam over your tip-end flat to prevent tip blowout.

- Reinforce seams between foam with duct tape, but avoid putting duct tape on striking surfaces.

Making a Sheath

One method of building a sidearm device uses a belt, four rivets, and three snaps. You will also need a strip of leather long enough to wrap around the grip of your weapon, plus 20" to 30". It's a good idea to use an oversized pommel on the weapon you wish to sidearm so that it will hang from the sidearm device without falling out. The belt can be purchased from Wal-Mart and a second belt can be cut up instead of the strip of leather. Make sure the belt fits over your garb. This is more expensive than just buying strips of leather, but is easier to acquire. The rivets and snaps can be acquired from a hobby store or leather store, but make sure they are long enough to fit all the way through two layers of leather. You may also need a leather punch. I recommend avoiding the ones from regular hobby stores, as they dull very quickly. You can also manage with a drill or a hammer and sharp knife, in a pinch. Dye the leather the color you want now, as it is very difficult later in the project.

The belt's purpose is to give something for the sidearm device to hold onto. It’s recommended to attach your sidearm device to the belt and not to any armour you may have. Put on your garb or armour, then the belt, and then make sure the belt does not rotate around your body or slide up and down your body too much. If you give a hard pull on the belt and it stays more or less in place, you are in good shape.

Put seven marks where you want the weapon to hang while wearing the belt with something temporary. Place the strip of leather that will hold your weapon against the belt, and put holes in, starting close to one end, so that you can put four rivets in, like this:

- O X O X O X O

Where O is a rivet holding the loop, and X is a mark. Don't actually put the rivets in yet, but put holes in the leather strip (but not the belt) where the X's are. Hold the strip against the belt, then put the weapon above where the last rivet away from the end. Wrap the leather around the grip, hold the leather loop in place, and remove the belt. Push your marker through the holes where X is above, so that your buttons will line up. Add both ends of the button to the loop. What you'll now have is this on the leather strip where you made your marks before:

- R S R S R S

Where R is a rivet, which lines up with the belt, and S is a snap, which lines up with the snap on the other end of the leather.

You will find that if you use one or two snaps, they will tend to come loose at inopportune times. Four or more is overdoing it, but does not have any functional problems. If you wrap the leather too tightly around the grip, the snap tends to pop open, which is why you want to use a large pommel. You need a weapon/sidearm device combination that the grip can fit through the device but the pommel cannot. A good pull of the weapon in the direction of the snaps will cause the weapon to come out.

A simpler design is a loop of leather, riveted to itself (use two rivets, just in case), which then fits over a belt. You will then need to add one part of a button to the bottom, and a short strip of leather riveted close to the closed loop with the other half of a button on that end. Make sure that the button sticks out: If it sticks upward, the weapon won't come out when you need it, and if it sticks downward the weapon may not stay put when you run.

This method does not construct anything that visually resembles a sheath, but does create a piece of attire which can hold a weapon when it needs to, and release the weapon when it needs to.