Updated Blue Sword Tutorial

THIS IS A WORK IN PROGRESS!!! I am using the old pictures as placeholders for now.

Basic Instructions

These instructions are for a beginner level sword. If this is your first weapon, you're doing it right so far by coming here!

Materials/Tools Needed

- 1/2" fiberglass. If you don't have access to any, 3/8" fiberglass or 1/2" PVC will suffice for lengths out to 27" or so.

- DAP Contact Cement

- Blue camp pad

- Strapping tape

- Duct tape

- cloth tape. Most commonly comes in both black and white. Black will not show dirt.

- Carpet tape

- Color tape Blue, and green if you decide to make a stabbing sword.

- 1/8-3/8" rope

- Cover fabric, preferably trigger

- hacksaw

- Straight edge of some sort, be it a (preferably metal) yardstick, ruler, etc.

- Razor blades. You will need lots of these. Having a fresh sharp edge will help you make better weapons.

- Sand paper

- Permanent marker

Instructions

1) Using a hacksaw, cut your core to your desired length. Keep in mind that about 2" of foam will contribute to the total length of your sword. Most veterans recommend a 30-34" length sword. Mark your desired handle length, allowing about 2 in. for the pommel. Remember that the maximum handle length for a blue weapon is 18" or 1/3 of the overall length, whichever is greater. The handle can't be more than 1/2 of the total length of your sword.

For this one, we're going with about a six inch handle.

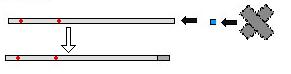

2) Sand the sharp edges around the tip of your core, then take a 1/2" x1/2" scrap of foam and place it on top of your core. Using an X of two 1/2" wide lengths of strapping tape, secure this little scrap (commonly referred to by foamsmiths as a "biscuit",) to the top of your core, compressing it about 20-30%. Then, wrap this whole configuration horizontally with a single layer of strapping tape. This process is called "biscuiting" and ensures your core will not cut away at the inside of your sword blade.

Next, sand the entire blade length, including the biscuit assembly. Ideally, you want to sand strapping tape just enough to remove that glossiness. Remove the dust with a slightly damp cloth and dry your core if needed.

3) Cut a strip of blue camp pad that's as wide as your core and slightly longer than twice your sword blade. It's important that your cuts are as neat and clean as possible; any wonky cuts in this layer will affect the overall integrity of your sword. This is where having fresh razor blades and a straight edge really helps.

After making several cuts, you may notice your blade dulling and in need of replacement. Razor blades are quite cheap, so don't feel as if you have to be stingy with them!

4) READ THE DAP INSTRUCTIONS CAREFULLY!! Dap one side of your blue foam strip and evenly around your core from the top of your handle mark upwards toward the tip of your blade that you biscuited. When both your core and your foam strip are dry and tacky (about as tacky as a post-it note, usually takes 15 minutes or so, depending on temperature and humidity), stick the strip onto the edge of your core, starting at the bottom of your blade and going all the way up, over, and down the other side.

Be very careful to make sure this strip is adhered as straight as possible. Also pay attention to your coat of dap; you do not want it too thin or thick, otherwise it will not bond properly. Working with dap takes patience, and if you don't have access to the guidance of an experienced foamsmith, it may take some trial and error to use it properly.

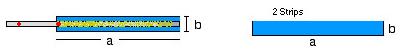

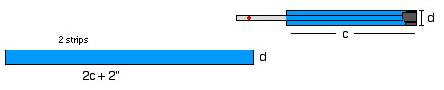

5) Cut two strips of blue foam with dimensions as long as and as wide as your blade at this point, again making sure to cut neatly and carefully. Do not worry about rounding the tips of these strips for now.

6) Glue and attach these two strips of foam, one on each side of your core, to make a 'box' of foam around your core. Start at the tip on each side and work your way down, making sure your two foam pieces line up smoothly. Make sure all the seams adhere properly by gently squeezing.

7) Trim the corners at the tip flush with the thin strip of foam. It's best to do this with a fresh blade. Trim the excess at the bottom too.

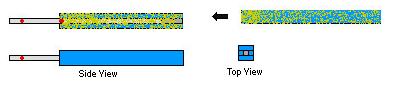

8) Rotate your sword so the thinner strips of foam making up your box are facing you. Cut two strips of blue foam as wide as this side and a little more than twice the length of your total blade.

9) Glue along one side of one of your long foam strips. Glue on the edges of your foam box with the thin foam strips showing, and the top of your box.

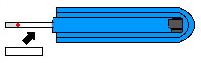

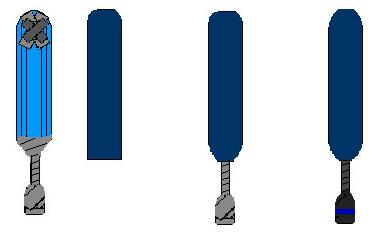

Attach your long strip of foam over the glued portions of your box once everything is dry and tacky. This is your first 'blade' layer. When finished, it should look like this:

10) Repeat step 9 by attaching your next long foam strip and building up your 'blade' padding. Your side view should look like this, once complete.

You can now add a stabbing tip if you so choose.

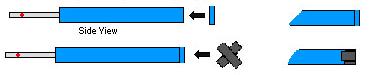

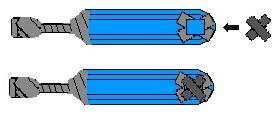

11) Now it's time to add the pommel. Biscuit the opposite end of your core like you did above, except this time it is not necessary to sand the strapping tape. Cut a length of blue foam about eight" long and a about 1.5" wide (we don't need to be exact here). Bevel one end of this strip using a razor blade. Using carpet tape, spiral wrap this blue foam strip twice around and trim flush, as illustrated below:

(pretty pictures)

Carpet tape two squares of foam to the bottom. Remember your pommel must not pass through a 2" hole, so adjust accordingly. Trim these squares to a more round shape. Wrap your entire pommel in duct tape, taking care not to compress the foam.

(moar pics)

Next, take a strip of cloth tape and tape over the bottom of the pommel, extending down either side and attaching to the core. Repeat until the entire pommel is covered in tape. Depending on the width of the cloth tape, it is possible to do this with as little as three strips. One complete, tightly wrap the cloth tape connected to the core with more cloth tape. This will help secure the pommel.

(pretty pommel montage)

12)To expand a thin fiberglass core, you'll want to wrap your grip in rope. This is unnecessary for PVC.

Rope wrapping: Cut a strip of carpet tape the length of your handle. Place it between the base of your blade and the top of your pommel.

Tightly wrap your rope of desired thickness (3/8" is good) around the carpet taped portion of the handle, starting and finishing by securing the rope with a strip of cloth tape.

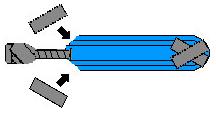

13) Using the hacksaw, shave off two chunks at the base at a 45 degree angle. This will allow your sword's cover to fit better as well as prevent the foam at the base of your sword from shearing. Place two strips of cloth tape over the sheared area.

14) Run a strip of duct tape along each flat. For extra tip security, put an X of duct tape over the point where your core resides underneath your foam on both sides.

15) Finish by making a cover and marking the color class accordingly.

You now have a (hopefully) functional Belegarth-legal sword! Hooray!

Helpful Tips

- 1/2" fiberglass rods typically come in lengths of 5'. Cutting these in half will yield two well-sized cores, which you can build up at the same time.

- Using a scrap of bluefoam as a 'dap-licator' works just fine; no need to waste your money on foam brushes, as cheap as they are.

- Keep the razor blade as perpendicular to the foam as you can when cutting. As stated above, neat clean cuts will not only help your weapon last longer, but also improve the overall appearance of the weapon. Experiment with different methods of cutting to find out what works best for you.

- Gluing a rectangle of foam on each flat near the tip may help curtail tip blowout, especially if you have a stabbing tip.

- Some foamsmiths prefer to sand the surface of their foam prior to dapping to maximize its surface area. While sanding is important for your core, it's debatable if it significantly helps better adhere foam or not.

- Allow the dap to cure for at least two days before using your weapon. A good rule of thumb is when your weapon no longer smells like dap, it is ready for combat.

- Avoid putting pressure on your sword blade during storage. Ideally, a sword should be stored laid flat with nothing on top of it.

- Gripping your sword by the pommel, or 'pommel fighting,' will cause your pommel to break down quickly and require you to replace it more often.

Advanced Methods

~coming soon~